Reducing Trade Show Labor Costs

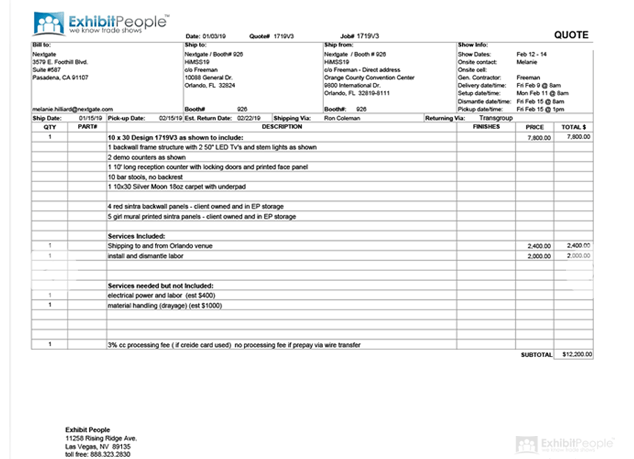

Install and dismantle labor can be costly so taking measures to reduce trade show labor costs can save you a sizable portion of your exhibiting costs. Some of the factors that can increase these costs are the rental booth design, how it’s packed, the skill and experience of the install workers and whether the show install and/or dismantle hours fall during union overtime hours.

Other less obvious factors, like booth location on the show floor or unforeseen delays can all add up to a sizable labor bill. And if all that wasn’t enough, many labor companies will tack on a 30% supervision fee when you’re not at the booth space to oversee the install or dismantle.

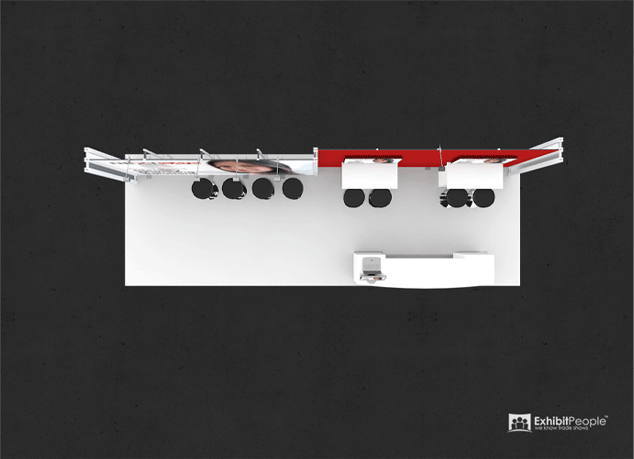

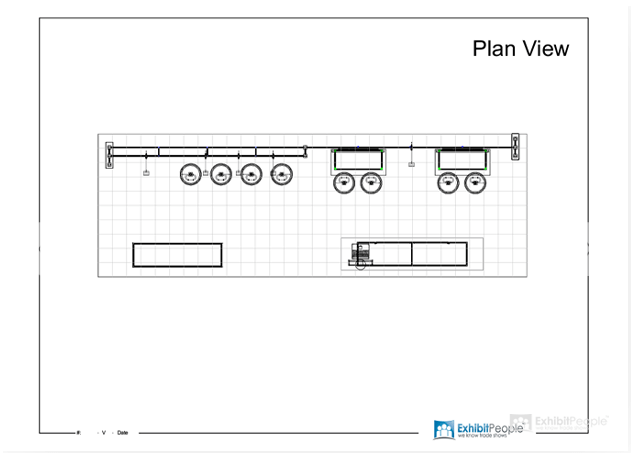

One of the best ways to to minimize your trade show labor costs is by having a well coordinated install with an experienced install supervisor familiar with your booth. We send an Install Supervisor on every booth set-up and dismantle. Sending a set of renderings, drawings, and layouts to the supervisor will help the install team to hit the ground running and they can be on the lookout for any potential issues that could delay the install.

Finally, Union labor rules apply at most shows. Some shows and some venues are more strict than others. Orlando, for example, may be the most relaxed city in terms of Union restrictions. We don’t recommend installing your booth without Union labor. The Trade Show industry is relatively small, and its best to comply when needed and come away with a network of local people that want to work for you again in the future.

We Help You Reduce Your Trade Show Labor Costs

Our best strategy for reducing trade show labor costs is to come prepared to the show with an Exhibit People install supervisor. Not only do we know your rental booth design inside and out, we know how it was packed and the most efficient way of staging the materials. We arrive to the show site with a game plan and goals to accomplish to help ensure that we don’t exceed the number of hours planned.

When it makes sense, we send portions of the booth partially assembled, reducing install time and shipping costs. We start each install with a brief meeting to make sure everyone is clear on the details and the milestones. We always check electrical floor work to ensure outlets are positioned properly before we install flooring. From there we build the booth systematically in a manner that keeps tools and materials organized and the booth space clean.

Here’s what matters:

- More workers doesn't always mean faster install

- A clean work area promotes efficiency

- Plan to be onsite or nearby during install

- Plan work during regular hours whenever possible